Line Up, Single File

MAFES scientist keeps an (artificial) eye on the future of catfish processing

By: Meg Henderson

The information presented on this page may be dated. It may refer to situations which have changed or people who are no longer affiliated with the university. It is archived as part of Mississippi State University's history.

Artificial intelligence touches nearly every aspect of our lives today, down to the food on our plates. And automated systems using robotics and machine vision technology are becoming more prevalent in crop fields across the globe. Today, a scientist in the Mississippi Agricultural and Forestry Experiment Station (MAFES) seeks to apply that kind of technology to aquaculture—specifically catfish.

For the last four decades, Mississippi has led the country in the multi-billion-dollar catfish industry, with production driving economic activity and employment in several Mississippi counties. However, labor shortages and rising labor costs—along with international market competition and pandemic-related supply chain disruptions—have slowed U.S. catfish production in recent years.

The singulation process—where frozen trimmed fillets are separated and flattened before being sent for breading or quick freezing—is a critical step that has always been done by hand due to catfish's delicate consistency and tendency to stick together when frozen. But artificial intelligence and computer vision systems may be able to fill the much-needed role in this process while reducing labor dependence and increasing profitability.

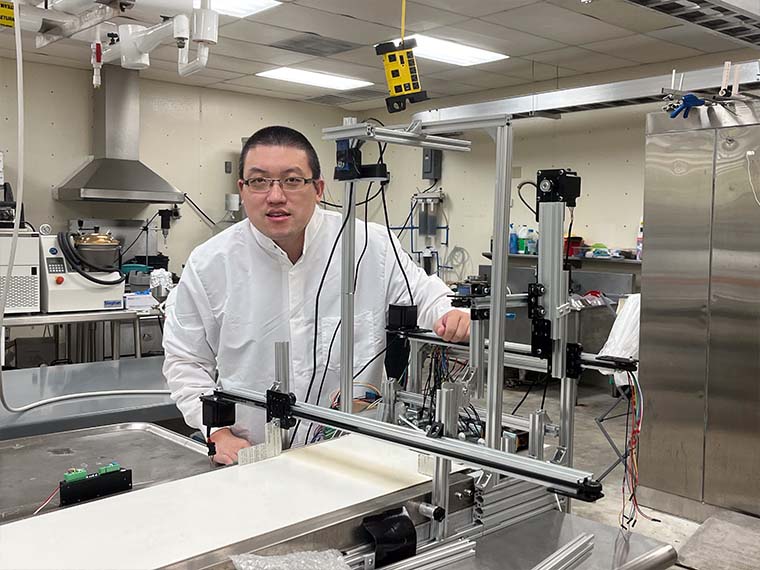

Dr. Wenbo Liu, principal investigator and assistant professor in the Department of Agricultural and Biological Engineering at Mississippi State, is conducting this research at the MAFES Experimental Seafood Processing Laboratory in Pascagoula. Liu has teamed with co-principal investigator Dr. Yuzhen Lu, assistant professor in the Department for Biosystems and Agricultural Engineering at Michigan State University and machine/computer vision specialist, to create an exciting new prototype.

"We're seeing computer vision technology increasingly used in the food industry for tasks like fish species recognition and yield production, but research on orientation and singulation of fish fillets is limited," said Liu.

The team has built a novel robotic singulation machine that uses water buoyancy and underwater jets to separate catfish fillets. A high-resolution camera collects images of the catfish fillets and works with SegFormer-b5 and YOLO v8 machine learning models, which the team trained to detect fillet orientation.

The machine works by moving a batch of fillets down a conveyor belt and dropping them into a tank, where a wavemaker begins to separate them. To begin the singulation process, a central water jet sprays the fillets with a circular motion, then sidewall jets blast the fillets to further separate, flatten, and correctly orient them. Finally, a vacuum gripper picks up the individual fillets, which are then ready for final processing steps. The computer vision system keeps an "eye" on the fillets and guides the entire process.

"Singulation is a labor-intensive and costly process," said Liu. "Due to their long, thin shape and soft texture, catfish fillets are not suited well to existing mechanical seafood singulation systems. They must be oriented precisely with the head in front and tail in the rear—otherwise, the tail section may get stuck in the gaps between conveyor belts or bed plates."

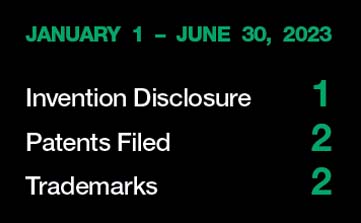

The team has applied for funding from the Strengthening Mississippi Academic Research Through Business Act (SMART Business Act) and a United States Department of Agriculture National Institute of Food and Agriculture seed proposal, both of which are under review. The recently established SMART Business Act is an MSU-driven initiative supporting university research to develop state-owned intellectual property into commercially viable products and services.

"We've applied for a patent but still have a long way to go before we have a system ready for commercial use," said Liu. "We plan on working to increase the processing speed of the prototype, and, in a commercial setting, we would also want to integrate the singulation process with other manufacturing steps."

This research is funded by the Mississippi Agricultural and Forestry Experiment Station.