The information presented on this page may be dated. It may refer to situations which have changed or people who are no longer affiliated with the university. It is archived as part of Mississippi State University's history.

Disruption during the COVID-19 pandemic laid bare vulnerabilities around the country's meat supply. According to the U.S. Department of Agriculture, 85 percent of all U.S. grain-finished cattle is processed by four companies. As the plants of these companies experienced disruptions like temporary closures during the height of the pandemic, the effect on the supply chain lasted weeks.

As part of the American Rescue Plan, the federal government has made a $500 million investment to expand meat and poultry processing capacity to improve meat supply chain resilience. Mississippi's small-scale meat producers and processors have risen to the occasion to help diversify the supply chain. Researchers in the Mississippi Agricultural and Forestry Experiment Station (MAFES) are working to provide these producers and processors with vital information so that the farm-direct meat industry can grow and thrive.

Dr. Derris Devost-Burnett, associate professor in the Department of Animal and Dairy Sciences at Mississippi State University (MSU), and his team are building a database to better understand what the farm-direct meat market will bear.

"Our plan is to generate a farm-direct database complete with empirical data from livestock processed at our USDA-inspected facility as well as participating local abattoirs," he said.

The team will address dressing percentage (hot carcass weight as a percentage of the live weight of an animal at harvest), cooler shrink (the loss of weight as the carcass cools and water evaporates), optimal aging times, and processing options to maximize the yield and quality of farm-direct products. They will perform an economic analysis of everything that goes into bringing a meat animal to market, including feed costs, processing, break-even marketing, and value-added processing for increased profitability.

"Based on these data, we will model optimization scenarios to maximize yield and the value of carcass fabrication and processing. We will develop models based on these various inputs and value-added scenarios to maximize the value and efficiency of the local farm-direct industry," Devost-Burnett said.

While databases exist for the larger meat processing sector, that data doesn't translate to small-scale production. Devost-Burnett said large and small processors operate in a completely different manner with small-scale processors harvesting between 10 and 20 animals a day and often harvesting one animal at a time while large processors may harvest up to 4,000 a day in a more automated, assembly-line fashion. The animals brought to market also vary in size and composition.

"The farm-direct supply chain does not typically involve the intensive feedlot finishing as is practiced in commercial markets where those animals are finished to commercial endpoints for weight and composition. As such, the yields and composition of the resulting meat products vary and aren't clearly understood by producers new to the farm-direct market. Those producers need this data to define their production targets, market price, and retail strategies to remain profitable," he explained.

Devost-Burnett said the work will impact producers, processors, and consumers all for the better and increase the sustainability of the system overall.

"Producers need consistency in terms of predicted yield and performance of their meat animals; processors and retailers need reliable data regarding the most effective processing techniques to maximize the quality and quantity of products they process and market; and consumers need confidence in consistent eating quality, pricing, and flavor of their farm-direct meat products," he said.

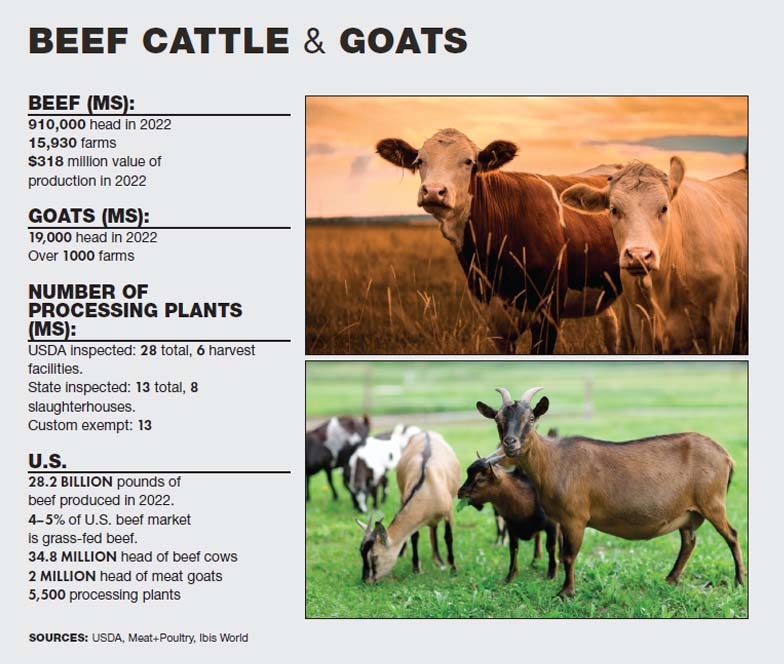

The team will start with beef cattle and meat goats, purchasing six market beef between 900 to 1,400 pounds in 100-pound increments and ten market goats between 60 and 160 pounds in 10-pound increments. They will also collect data from university research, local processing plants, and beef and goat producers. Much of the meat goat data will come from a three-year myology study in partnership with Tuskegee University.

Dr. Leyla Rios de Alvarez, assistant professor in the Department of Animal and Dairy Sciences and MAFES scientist specializing in small ruminants, is part of the team that will partner with Tuskegee University and local farmers to establish best production practices for goat farmers, of which there are more than 1,000 in Mississippi.

"Our goal is to increase the viability of small-scale goat producers and processors in the Southeast by conducting a comprehensive myology investigation using meat goats reared under three practical production scenarios," she explained.

Sixty weaned goats will be studied under one of three scenarios: intensive feeding, browsing, and organic transitioning, then fed for 90 days. The intensive feeding group will be intensively managed in a confined feed setting and destined for market on a defined schedule. The browsing group will be used to manage land or clear browse and be intentionally managed to produce high quality goat meat. The organic transitioning group will focus on management strategies used in organic goat farming; this group will double as a training model for future goat producers interested in transitioning to organic goat farming.

The first year the research will take place at Mississippi State University and the Caprine Research Unit at Tuskegee. Trials will be replicated in year two on the farms of local Mississippi and Alabama goat farmers. From there, the team will assess the scenarios and determine best practices that can then be used in the database to develop further modeling scenarios.

"These data will be used to develop fabrication and processing techniques to increase the consistency, sustainability, and profitability of farm to fork goat meat marketing," Rios de Alvarez said. "The study will address a critical research need for the meat goat industry and will be immediately impactful to producers, processors, retailers, and consumers."

In addition to this research, which is funded by a MAFES Special Research Initiative grant, the team also recently received a grant from Southern Sustainable Agriculture Research and Education, or SARE, to build a mobile processing unit.

MAFES researchers are excited to make a difference for small-scale producers and processors as the farm-direct industry grows in Mississippi to help augment the commercial meat processing sector.

"The farm-direct pipeline is an opportunity for rural agricultural businesses to grow, and it provides local benefits for producers, processors, consumers, and communities alike. We learned during the pandemic that our meat supply chain is very consolidated, which proves efficient when things are working well. That consolidation, however, makes it vulnerable to disruptions and unforeseen circumstances. Diversifying the supply chain helps to bolster our resilience," Devost-Burnett said.

He added that consumer demand is further driving the farm-direct market.

"In many cases, consumers are willing to pay a premium because they realize for the same reasons that it costs more, it's a process that isn't automated, where there is a story behind the meat and they can have direct communication and build a relationship with their farmer," Devost-Burnett said.

"Our goal is to help those producers and processors build and expand on sustainable and thriving businesses while meeting consumer demand and expectation."

This research is funded by the Mississippi Agricultural and Forestry Experiment Station (MAFES) Special Research Initiative Grant and the Southern Sustainable Agriculture Research and Education (SARE).

The farm-direct pipeline is an opportunity for rural agricultural businesses to grow, and it provides local benefits for producers, processors, consumers, and communities alike. We learned during the pandemic that our meat supply chain is very consolidated, which proves efficient when things are working well. That consolidation, however, makes it vulnerable to disruptions and unforeseen circumstances. Diversifying the supply chain helps to bolster our resilience.

Dr. Derris Devost-Burnett

Behind the Science

Derris Devost-Burnett

Assistant Professor

Education: B.S., M.S., Animal and Poultry Sciences, Tuskegee University; Ph.D., Animal Science, Auburn University

Years At MSU: 8

Focus: Pre- and post-harvest factors that impact meat composition and quality

Passion At Work: Understanding pre- and post-harvest factors to influence muscle composition and meat quality has both agricultural and biomedical implications for humans and livestock.

Leyla Rios de Alvarez

Assistant Professor

Education: B.S., Animal Science, M.S., Animal Production/Animal Nutrition, Universidad Central de Venezuela; Ph.D., Interaction Nutrition-Parasites, University of Edinburgh

Years At MSU: 3

Focus: Use of bioactive forages and plant extracts for sheep and goat parasite control and welfare of foraging sheep and goats

Passion At Work: Small ruminants are easy to produce in small spaces, require a low initial investment, produce high-quality protein food, and can be produced with family manpower.