Fashioning face masks

Fashion designers and engineers collaborate on face masks and testing apparatus

By: Karen Brasher

The information presented on this page may be dated. It may refer to situations which have changed or people who are no longer affiliated with the university. It is archived as part of Mississippi State University's history.

FOR OVER A YEAR, people throughout the world have added an unexpected accessory to their attire: a face mask. With the advent of COVID-19, face masks have become personal protection items, and in some cases, a fashion statement. However, all masks are not created equal. So which masks provide the best protection?

That is the question that professional and collegiate athletic departments, and apparel manufacturers and merchandisers asked engineers at Mississippi State's Institute for Clean Energy Technology (ICET), a research center uniquely positioned to provide answers, having worked alongside industries to solve problems for more than four decades. At the time, ICET had the capacity to test flat media, in accordance with standards set forth by ASTM International, formerly known as the American Society for Testing and Materials.

"As COVID-19 hit the U.S., many apparel companies were adding face masks to their apparel lines or switching their focus to production of face masks," said Jaime Rickert, interim director of the Institute for Clean Energy Technology. "Several companies were requesting testing to determine which fabrics or combinations of fabrics met the ASTM standards. One company that requested testing was Tupelo-based Blue Delta Jeans."

Blue Delta Jeans, purveyors of high-quality custom blue jeans, had staked its reputation on small-batch, locally-crafted raw denim. The integrity built into their business model carried over as they shifted focus to mask-making, which also afforded the company the opportunity to keep seamstresses sewing during the historic economic downturn.

This was not the first time Blue Delta Jeans has turned to the university for guidance. The apparel manufacturer frequently works with Dr. Charles Freeman, a fashion design and merchandising associate professor in the School of Human Sciences, and a Mississippi Agricultural and Forestry Experiment Station scientist. When ICET results came in, the apparel designer contacted Freeman to discuss the outcomes.

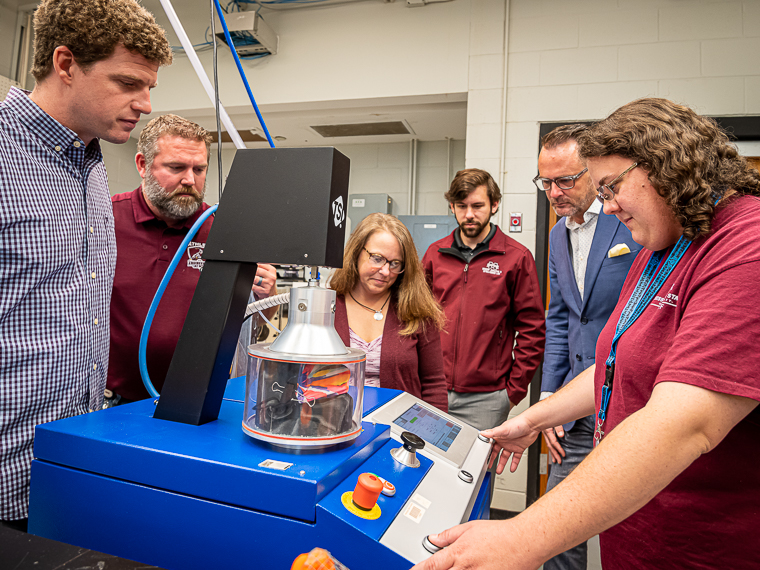

This discussion led to the creation of an interdisciplinary team of fashion designers, engineers, and sports trainers. The unique, visionary team not only addressed questions posed by industry affiliates but also developed two separate patent-pending inventions.

While ICET could test the fabrics as flat media according to the standards, this method was not representative of how a mask is worn and didn't account for the contours of the human face. Freeman turned to a familiar prop-a mannequin-to design and print a 3-D face filtration mount, adapted from CPR heads and facial molds, that resembled the average size of a human head and mouth.

Head in hand, Freeman went to ICET to see if the face mount would work with their testing equipment. The mount worked great, but it didn't align with the ASTM International standards for testing. The team reached out to the Centers for Disease Control and Prevention (CDC) for guidance. "When we discussed the testing methods with personnel from the CDC, we found that our methods were in line with new standards the CDC was developing in collaboration with ASTM International for testing nonsurgical fabric masks," Freeman said.

Encouraged by the CDC to continue the work, the team began testing fabric masks for filtration efficiency and airflow resistance. Filtration efficiency measures the particles stopped and retained by the mask while airflow resistance measures the air permeability or how much air goes through the material.

The scientists selected 11 consumer, non-medical, fabric masks to test. Two and three-layer masks containing nylon, cotton, spandex, bamboo, foam, and polyester, either alone or blended, were tested. Double-sided tape was used at the bridge of the nose, under the chin, and along the jawbone to affix the mask to the 3-D face filtration mount.

The tested masks included an assortment of materials and construction methods, which made discerning the quality, efficiency, and difference in protection levels from one mask to the next a challenging proposition. To test a mask, two aerosol generators, one oil-based and one saline-based were used, generating particles the size of the COVID-19 virus.

Five tests for each mask were conducted. None of the masks met ASTM International's minimum standard for filtration efficiency for nonsurgical face coverings, however, some tested masks performed better than others. All the tested masks exceeded the minimum standard for airflow resistance.

"None of the face masks we tested in the market met the new standards released by ASTM International for nonsurgical masks," Freeman said. "Aside from discomfort, current face coverings can fog eyewear and have gaps around the jawbone."

The team decided to design a better face mask, one that would pass the ASTM standards but would also combine all of the best functionalities afforded in a face covering.

The newly designed, patent pending MSU Face Barrier Covering was created to maximize direct skin contact to provide additional support and limit overall discomfort as well as leakage around the edges of the mask. A fit and gapping analysis, developed in collaboration with Louisiana State University, indicates the design is under 12 percent leakage compared to 80-90 percent for currently available masks. Less leakage provides more containment of the virus through face coverings.

Once again, the group contacted the CDC to discuss their findings.

"The CDC personnel were impressed with the design, particularly the method to measure leakage, something that had not been previously quantified," said Dr. Reuben Burch, associate director of Human Factors and Athlete Engineering at CAVS. "In a short period of time, our team was able to reverse engineer the testing methods for mask filtration and use our new face mount fixture to measure leakage."

Louisiana State University scientists with expertise in fit analysis and vapor visualization joined the research project to provide further analysis.

Scientists hope to license the face mask and mount designs to manufacturers as the market predicts that nonsurgical face masks, in some form, will become a semi-permanent fashion accessory. In fact, the reusable fabric mask market is projected to be at $7 billion by 2027 and masks sold in the U.S. will be only be certified if they pass the standards set by ASTM International.

Until the new mask is manufactured, Freeman notes that the study is not intended to discourage the use of mask wearing but rather to inform manufacturers and consumers.

"Previous studies have shown that masks provide a critical disruptor to airflow, creating turbulence," he said. "Our research concurs with this finding, as turbulence limits the distance particles can travel away from an infected individual."

Freeman added, "Masks provide one piece of protection to prevent the spread of COVID-19 and when used with the suite of CDC guidelines, can help stop the spread of the virus. Ensuring that masks meet the ASTM International guidelines is important as manufacturers continue to design products for this market."

In addition to Freeman, Rickert, and Burch, the team includes Dr. Catherine Black, professor in the School of Human Sciences; fashion design and merchandising majors Sarah Ashley Bealor, Madison Ratledge, Abigail Nicholas, and Sydney Fava; Dr. Leslie Strawderman, professor and endowed chair in the Department of Industrial and Systems Engineering; David Saucier, research engineer at CAVS; John Wilson, research engineer in ICET; Dr. Brian Smith, associate professor in the Department of Industrial and System Engineering; Dr. Charlie Waggoner, retired professor and director, ICET; Courtney Taylor, vice president at The Communiversity for East Mississippi Community College; Gregory Skaggs, director of athlete performance for the Tampa Bay Buccaneers; and Thomas Callans, assistant MSU athletic director for sports medicine and head athletic trainer for football. Both the testing apparatus and face covering are patent-pending. The MSU Face Barrier Covering design has been submitted to the Department of Health and Human Services Biomedical Advanced Research and Development Agency (BARDA) National Mask Innovation Challenge. To learn more about licensing, contact Jim Mitchell, licensing associate in the MSU Office of Technology Management, via email at jfm93@msstate.edu or call 662-325-8223.